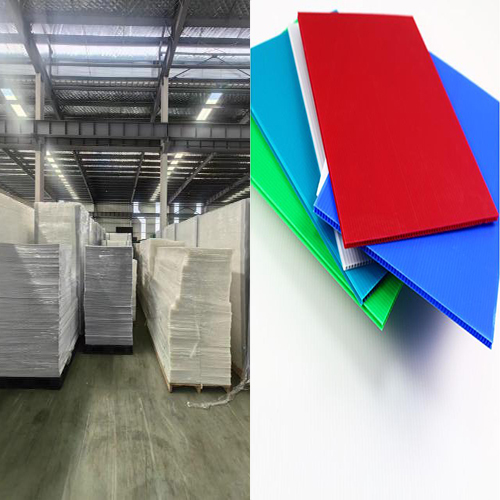

Coroplast sheets, which are also known as hollow lattice board, vantone board, corrugated board or double wall board, the English name is corrugated plastic sheets. It has been widely used in many fields because of its unique hollow structure, light weight, non-toxic, pollution-free, waterproof, shock-proof, anti-aging, corrosion-resistant and rich color.

Production materials and technology:

Coroplast sheets are mainly made of environmentally friendly and pollution-free recyclable polypropylene (PP). These raw materials are processed by extrusion molding, which makes the hollow plate not only light in weight, but also has excellent mechanical properties. At the same time, the production process of coroplast sheets can also be customized according to customer’s needs, meeting the needs of different industries.

Main features:

Light and high strength: coroplast sheets adopt hollow structure, which is lighter in weight than traditional materials when achieving the same mechanical effect, easy to handle and install, reducing the cost.

Waterproof and shock-proof: Its special structure makes it have excellent waterproof, moisture-proof and shock-proof performance, which can effectively protect the internal items from damage.

Corrosion resistance: corrugated plastic sheets is non-toxic and tasteless, and it will not cause pollution to the environment, and it has good corrosion resistance, prolonging the service life.

Environmental protection and energy saving: corflute sheets have passed a series of environmental protection certification, which is in line with international environmental standards.

Versatility: It can be added according to the demand of anti-static, conductive masterbatch, etc.,producing the conductive and anti-static function. Therefore, it has wide application in the electronic industry packaging and other fields.

Application fields:

The application fields of coroplast sheets are extremely wide, mainly including electronics, packaging, machinery, logistics, construction and other industries. In the electronics industry, hollow plates are mainly used for the packaging of electronic parts to prevent spark damage caused by charge friction; In the field of packaging, it can be processed into various pp corrugated boxes. In the advertising industry, it is very suitable to make coroplast signs.

Huiyuansj is the top 3 coroplast manufacturer in china with rich export experience. The standard size of coroplast sheets are 4×8 corrugated plastic sheets. Source factory can customize production according to client’s needs. If you have interst in our coroplast products, welcome to contact us.

By continuing to use the site you agree to our privacy policy Terms and Conditions.