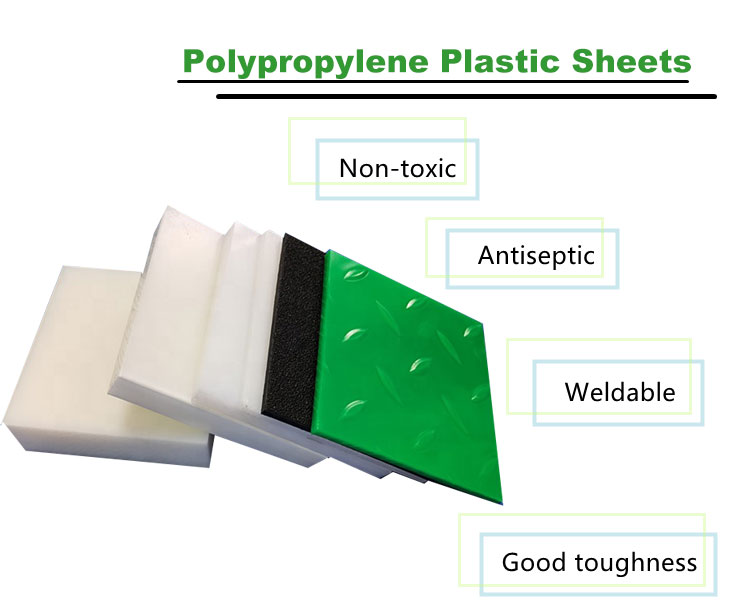

Polypropylene Insulation Sheets can be heat-formed, shaped, and welded to fabricate ducts, hoods, and much more. It has excellent corrosion resistance to a wide range of items. Cannot be cemented but is easily welded with a plastic welder. Can be cut with a carbide-tipped blade and drilled with regular metal bits. The polypropylene sheet has a .90 density. Rigid with fair impact resistance and very good abrasion resistance. It is white-tan, translucent with working temps of 40°F - 210°F and a forming temp of 310°F - 325°F. Color: White, Blake, Blue, Red, or Custom Width: Less than 3000mm Length: Any customized Thickness: 0.5mm-20mm, 30mm, 40mm, 50mm, 60mm, 70mm, 80mm, 90mm, 100mm Weight: 0.91-0.93GSM/m³ Delivery: 7-14 days Design: OEM/ODM Certificate: SGS, ISO9001

What are Polypropylene Insulation Sheets?

The non-polar structure of polypropylene insulation sheets and Rods gives it a very high molecular mass. This makes PP Sheet and Rod highly resistant to chemicals and to aqueous solutions of salts, acids, and alkalis.

PP plastic board has a high level of stiffness and toughness at room temperature. This together with their capacity to repel water makes them a good choice for mechanical and structural applications.

Key Features of polypropylene insulation sheets

Excellent moisture resistance

Very high chemical resistance

Excellent impact resistance

Food grade

Thermoformable

Work temperature between +5℃ and 100℃

Higher scratch resistance than HDPE

Parameters of Polypropylene Panels/boards/Sheets

| Description | Polypropylene Plastic Sheets/Panels/Boards | |

| Material | PP (polypropylene) | |

| Width (mm) | Max: 3000mm | |

| Length(mm) | Customized | |

| Thickness (mm) | 0.5-20 mm ; 20-100 mm | |

| Weight(g/sqm) | 0.91-0.93GSM/m³ | |

| Colors | Customized | |

Food or corrosive storage vessels

Cooling or scrubbing towers

Pump bodies and components

Wall cladding

Plating tanks and hoods

Benchtops

Except for pure semi-finished plastic material, we also can customize plastic properties according to the client's request.

Shapes: sheet, rod, tube, roll, plate, part

Special properties can be customized: plastic alloy, plastic +GF/CA/Oil/Brone/Graphit/MSO2/ceramic, etc.

Most regular thickness and standard size in stock, fast delivery

Support cut as request size, machined into parts

Forming method: extruding, mold pressing, casting, CNC machining

Lead Time: 10 ~ 15 days if not have in stock, 5 days for stocked items

Packing: carton box, IPPC wooden pallet/plastic pallet

Shipping: by sea, air, TNT/UPS/Fedex/DHL Express

Usually, the color and length can be customized, the width will according to the available extrusion mold or molding mold. Tolerance for length, width, diameter, and thickness may vary when manufacturing. Details please send us an email.

Suzhou Huiyuan Plastic Products Company has a complete quality management system, all our products have passed ISO9001 quality system certification, and its market share is increasing year by year. We regard credibility first, quality first, mutual benefit, and common development as the basis for our cooperation with customers. We have always tried our best to provide each customer with high-quality corrugated plastic products with reasonable prices and professional service.

If you need polypropylene plastic sheets, please don't hesitate to contact us. You can fill out the form below, or send an email to us, we will get back to you ASAP!

Any questions, please contact Huiyuan customer service freely at any time.

1. Free sample is available.

2. Rich variety of products.

3. Meet personalized requirements.

4. Can be customized according to your drawings.

5. Provide professional advice for your engineering design.

By continuing to use the site you agree to our privacy policy Terms and Conditions.