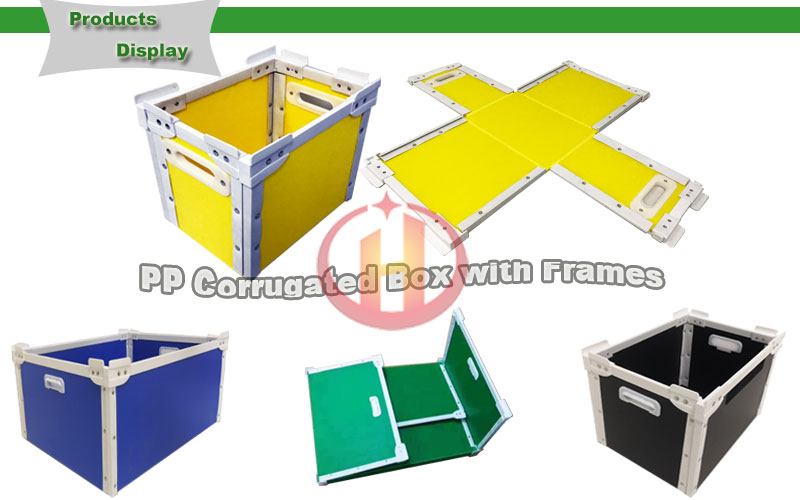

Corflute boxes are becoming a popular packaging choice for storage and shipping. In different countries, people also call them Corrugated Plastic Bin Boxes, Coroplast Boxes, Correx Boxes, Danpla Boxes, etc. PP corrugated boxes are available in a variety of shapes, sizes, and colors. These corflute boxes are lightweight, strong, and versatile, making them the first choice for distribution, transportation, and storage applications. In the market, we can see all kinds of Corrugated Plastic Bin Boxes, Huiyuan has developed the latest design - foldable coroplast boxes with frames.

Advantages of the corflute boxes

Custom Coroplast Boxes have better load-carrying capacity and stability by installing an injection-molded frame on each edge.

Huiyuan installs plastic handles on both sides of the box, which is convenient for workers to carry.

Recyclable, reusable, super long service life.

Foldable design, easy to install, save transportation cost, and reduce storage space.

Good weather resistance can adapt to all kinds of bad weather.

Good chemical resistance and will not rot.

Good waterproof performance, and will not soften in the rain like a carton.

We can also design custom linings or dividers that match the box according to customer requirements. It can not only maximize the use of space but also effectively avoid the collision between commodities.

The board for making the danpla box is a hollow structure, so it is very light in weight.

Affordable and durable.

The production process of the Corrugated Plastic Bin Boxes

First of all, the board for making the box is a board with a hollow structure through extrusion - PP flute sheets. Before producing PP corflute sheets, it is necessary to prepare the qualified raw material ratio.

Then, make precise cuts according to the designer's drawings. The crease needs to use a professional pressing and cutting machine.

If the customer requires printing, the contents are printed before the board is made into a box. Huiyuan offers screen printing, digital printing, and complex tri-color printing.

Use ultrasonic welding, rivets, or seamless welding to secure seams. Shape the box base.

Mount accessories such as handles, plastic frames, corner guards, etc.

We can also customize liners/dividers for you if you decide to use them to package your small auto parts or products like mugs. Corrugated plastic dividers need to be sized to fit inside the box so they can be easily put in and taken out.

Corflute boxes can also be designed with lids since the products that may be packaged are food-like and require good hygiene.

Applications of Custom Coroplast Boxes

Hardware industry

Daily necessities industry

Garment Industry

Retail industry

Food Industry

logistics industry

packaging industry

Auto parts industry

The danpla box can be upgraded to the special performance

If your corflute boxes need to be used outdoors for a long time, you need to choose the ones with better UV resistance to resist UV rays and prevent the boxes from aging.

If you plan to use our customized Corrugated Plastic Bin Boxes to package electronic products, we recommend you use esd packaging boxes. Just add anti-static particles to the raw material.

For some well-known companies, it is very important to print a representative logo or slogan. They need to tell people what brand they are in all the time. So we need to choose a box with very strong ink adhesion and not easy to fade.

For warehouse turnover, the most feared thing is fire. So you can choose to use flame-retardant Coroplast Boxes. Just add fire-resistant particles to the raw materials.

How to choose the ratio of raw materials?

The raw material of danpla box is environmentally friendly non-toxic polypropylene. The higher the hardness, the purer the polypropylene content, and the more expensive the price. Common corflute boxes on the market are brand new materials (100% PP), 7:3, 5:5, etc. If the customer does not have high requirements for hardness, a certain degree of recycled material will generally be mixed with the new material, which can not only meet the customer's quality requirements but also reduce the customer's budget. Therefore, choosing the right product is not necessarily the best raw material, but the most suitable material ratio for you.

Generally, if the Custom Coroplast Boxes are used for turnover and require long-term and long-distance turnover, choose 100% new materials. If it is a one-time package, you can choose to use recycled materials to reduce costs. Other ratios are based on the customer's application and budget.

Contact us to learn more about polypropylene corrugated products

Since its establishment, the company has always been market-oriented, serving customers as its purpose, strengthening the internal management of the company, and continuously meeting the needs of domestic and foreign customers.

The corrugated plastic products produced by the company have won the favor of many domestic and foreign customers with stable quality, reasonable price, and perfect service, and has established a long-term supply relationship with it. All kinds of corrugated plastic products sell well in Europe, America, Australia, Singapore, and other Southeast Asian countries.

If you want to buy corflute boxes, please don't hesitate to contact us, we will get back to you within 8 hours!

By continuing to use the site you agree to our privacy policy Terms and Conditions.