©Copyright 2019 Suzhou Huiyuan Plastic Products Co., Ltd All rights reserved. Terms and Conditions Designed by iwonder.cnSite Map

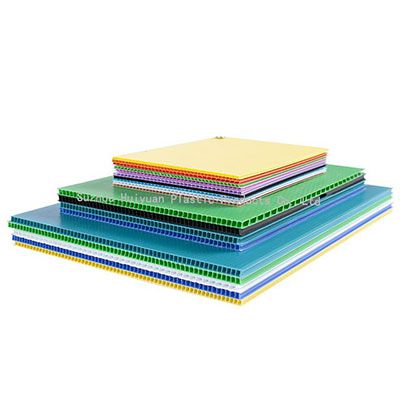

Also called plasticized cardboard or corrugated plastic or coroplast, it is formed by the union of two plastic cells known as flutes or ribs, which are composed of copolymer polyethylene.

Features

Corrugated plastic sheet is recyclable and light to work with. In addition, one of its significant features is its strength and capacity to absorb vibrations and impacts. This makes it perfect for indoors and outdoors thanks to its great performance in diverse environments, so it has no effect in contact with oils, solvents and water at normal temperatures. The surface is treated, making it suitable for digital printing with solvent-based, eco-solvent, latex and UV inks.

This material, compared to conventional cardboard, stands out for the benefits to be found when working with it, such as:

· High flexibility.

· Waterproof.

· Economic.

· Resistant to impact and even scratches.

· It can sometimes substitute for wood and cardboard.

· It can be silkscreen or vinyl.

· Easy to cut, glue and staple.

It should be noted that Coroplast benefits mean that this material can be found in different scenarios or places of the day to day, among the most prominent are:

· Stands.

· Packing.

· Plastic boxes.

· File boxes.

· Accessories for plastic boxes.

· Voting boxes.

· Printed sheets for advertising.

· Boxes for food.

· Exhibitors.

· Points of sale.

Some precautions you need to take when handling the corrugated plastic sheets

DRIVING

· Do not force the material to accommodate in a vehicle. Doing so may cause the material to deform. Only clean with a soft, damp cloth.

· Do not rub, scrape, use fibers, abrasive materials or solvents as this can damage the corona treatment and therefore prevent or make it difficult for the material to be properly printed.

· Preferably use gloves to handle the material since body fat can also damage the corona treatment.

· For smoothing, bending or other impact conditions, it is recommended to do between 10 ° C and 60 ° C. In other conditions the material may fracture or become "chewy". It must be tempered, or air conditioning used for processing if ambient conditions are outside of this temperature range.

STORAGE

· Avoid hitting the edges and corners.

· Do not expose to sunlight or excessive temperatures.

· Do not bend.

· Do not roll.

· Storage should be done in a horizontal positon on surfaces such as a pallet. It should never be stored in an upright position since plastic has memory and tends to retain the way it is placed, so it tends to deform, especially in the presence of heat.

· Avoid sources of ignition. Maintain good ventilation that protects the product from physical-chemical stresses, such as air temperature and humidity, saline air, water vapor and dust.

The uses and applications that can be given to coroplast are diverse and varied, some of them are file boxes, signs, mailboxes, stands, banners, advertisements, decoration, points of sale, displays, boxes for food, packaging, plastic boxes, boxes for agricultural products exposed to high humidity, printed sheets for advertising, ballot boxes, dividers with lamination of soft materials, boxes with antistatic application and some accessories for plastic boxes.

By continuing to use the site you agree to our privacy policy Terms and Conditions.